Description

Macstroc M-BEVELER Series – High-Performance ID-Mounted Pipe Beveling Machines in UAE

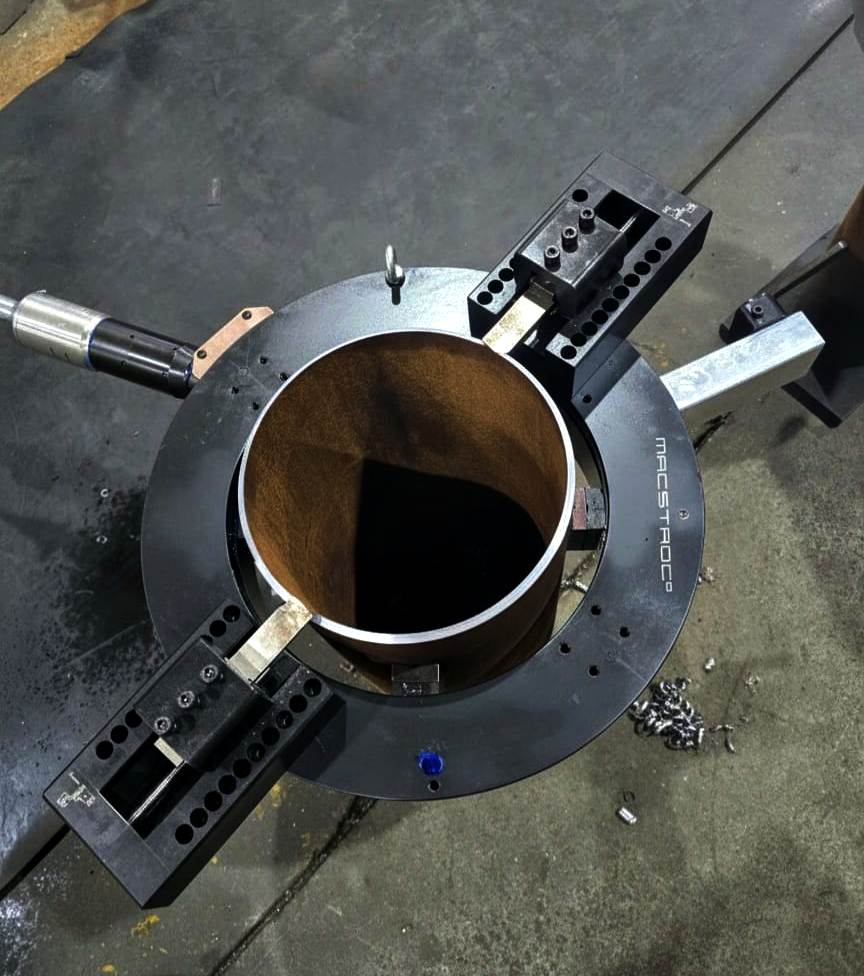

Macstroc proudly presents the M-BEVELER Series, a professional line of pipe beveling machines designed to deliver precision, portability, and durability in even the most demanding industrial environments. Engineered for excellence and trusted by professionals across the UAE, these machines are the ideal solution for pipe end preparation, ensuring a perfect weld prep edge every time.

Why Choose Macstroc M-BEVELER Pipe Beveling Machines?

The M-BEVELER Series features ID-mounted portable beveling machines that are compact, lightweight, and user-friendly. Designed for onsite operations, they are easy to set up and operate by a single technician. Whether you’re working on-site in construction, oil & gas, shipbuilding, fabrication, or plant maintenance, these machines are built to simplify your beveling process while maintaining the highest precision and efficiency.

Wide Clamping Range for Maximum Versatility

Macstroc’s beveling machines cater to a wide diameter range from Ø26 mm to 330 mm, ensuring compatibility with most pipe sizes commonly used in the industry. The various models — MPB79, MPB105, MPB170, and MPB330 — are available in both electric (E) and pneumatic (A) versions to suit different work environments. Whether you’re working in a high-explosive zone that requires pneumatic safety or a power-driven site, Macstroc has a beveling solution tailored for your needs.

Durable, Precise & Built for Tough Metals

These machines are specially designed to work with various grades of metal pipes, including carbon steel, stainless steel, and alloy steel. The bevelers are ideal for preparing edges of pipes, flanges, elbows, and pressure vessels before welding. Each machine delivers consistent results that reduce weld defects and improve joint integrity — critical for industries with zero-tolerance on failure.

The “T” shaped machine body ensures smooth operation in minimal radial working space, allowing it to fit in confined areas or congested pipeline environments. The rigid clamping system secures the pipe internally, keeping the cutting head steady during operation for an even and clean bevel.

| Model | Clamping Range Ø | Max. Wall Thickness | Max OD Ø | Voltage / Power / RPM | Weight (Electric / Air) |

|---|---|---|---|---|---|

| MPB79E / A | Ø26–79 mm | 15 mm | 89 mm | 220V, 1.1 kW, 9 RPM | 11 kg / 9 kg |

| MPB105E / A | Ø45–105 mm (1.77”-4.13”) | 15 mm | 125 mm | 220V, 1.43 kW, 34 RPM | 22 kg / 21 kg |

| MPB170E / A | Ø60–170 mm | 20 mm | 195 mm | 220V, 50/60 Hz | 27 kg / 26 kg |

| MPB330E / A | Ø150–330 mm (5.9”-13”) | 20 mm | 360 mm | 220V, 1.43 kW, 14 RPM | 68 kg / 66 kg |

|

PNEUMATIC MOTOR MPB-A |

|

AIR working pressure: 0.8mpa |

STANDARD TOOLS

|

DESCRIPTION |

CODE M35 |

CODE M42 – SS |

|

Tool 0° |

MBT-035 |

MBT-042 |

|

Tool 15° |

MBT-1535 |

MBT-1542 |

|

Tool 30° |

MBT-3035 |

MBT-3042 |

|

Tool 37° |

MBT-3735 |

MBT-3742 |

Applications Across Industries in UAE

Macstroc M-BEVELER machines are used widely in:

-

Oil & Gas projects in Abu Dhabi & Fujairah

-

Fabrication yards and steel workshops in Sharjah & Ajman

-

Water pipeline and infrastructure projects in Dubai

-

Petrochemical and energy sectors across Ras Al Khaimah and Al Ain

-

Shipbuilding and marine repair in Jebel Ali and Hamriyah Port

Whether you’re beveling pipe for welding or prepping for orbital welding systems, Macstroc machines deliver the edge — literally and technically.