Description

Macstroc MSCB Industrial Clamshell Pipe Cutting & Beveling Machine , UAE, KSA, Qatar, Oman, Bahrain

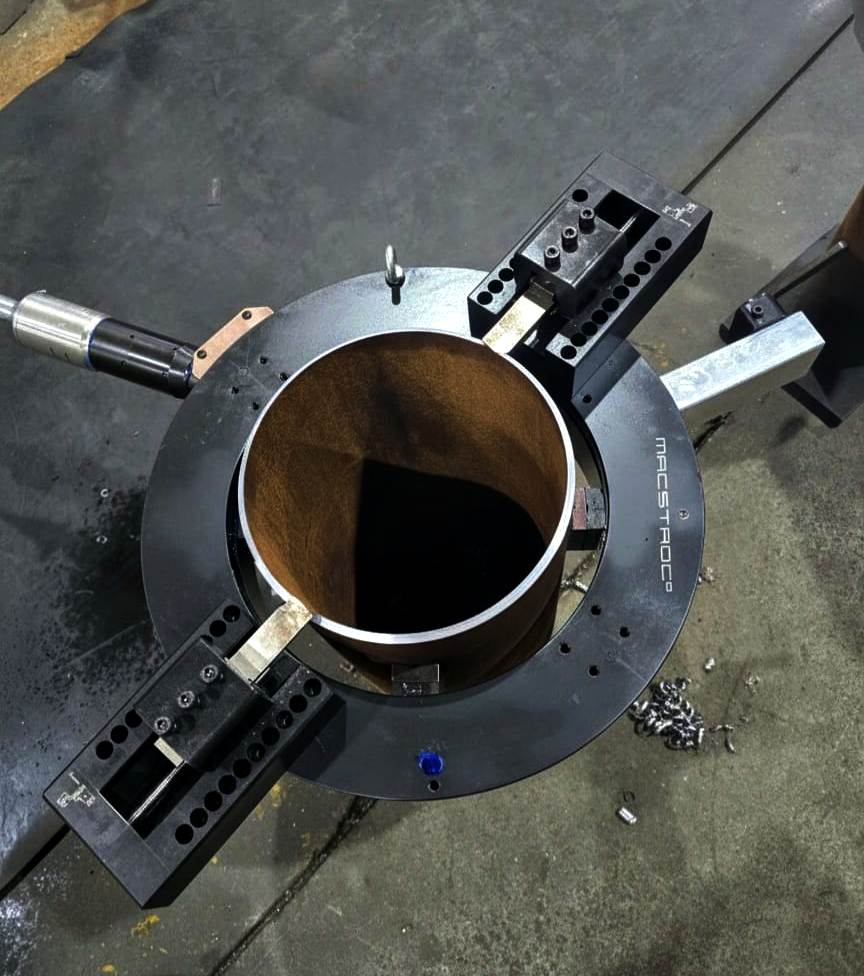

The MSCB Industrial Clamshell Pipe Cutting & Beveling Machine is a high-precision cold-cutting system engineered for professional pipeline fabrication and maintenance across oil & gas, petrochemical, power generation, shipbuilding, and construction industries. Designed with a rugged split-frame (clamshell) body, this machine opens around the pipe for easy installation, allowing operators to perform safe, accurate, and reliable cutting and beveling without heat, sparks, or distortion.

Built from a lightweight yet extremely durable aluminum alloy, the MSCB series is ideal for on-site work, shutdown jobs, offshore platforms, and confined spaces where traditional cutting equipment cannot be used. Its advanced clamshell design ensures maximum stability and perfect alignment, delivering consistently clean bevels for welding preparation.

The MSCB machine supports a wide range of pipe diameters—from 20mm up to 1420mm—with various drive systems to match every job requirement, including Electric, Pneumatic, Hydraulic, and Servo NC options. This provides flexibility for operations in hazardous zones, high-torque applications, or precision machining tasks.

Engineered for industry reliability, the MSCB offers multiple beveling configurations including U-Bevel, V-Bevel, J-Bevel, and custom profiles. High-performance tool bits (0°, 30°, 37°, 45°) ensure smooth and consistent bevel quality, minimizing preparation time before welding.

Whether used for pipe cutting, beveling, squaring, or facing, the MSCB delivers the accuracy needed to meet strict welding codes and quality standards. It has become a trusted machine across the UAE, Saudi Arabia, Qatar, Oman, and Bahrain for contractors and fabrication workshops that demand durability, speed, and precision under tough conditions.

The MSCB Industrial Clamshell Pipe Cutting & Beveling Machine is the ideal choice for companies looking to enhance productivity, ensure clean weld joints, and maintain the highest level of safety during pipeline operations.

| Split Frame Code | Working Range Ø | Max. Wall Thickness (mm) | RPM | Electric Version | Pneumatic Version | NC Version | Hydraulic Version |

|---|---|---|---|---|---|---|---|

| MSCB-90 | Ø20–90 mm (3/8″–3″) | 25 / – | 34 | MSCB-90E | MSCB-90A | MSCB-90N | MSCB-90H |

| MSCB-168 | Ø25–168 mm (1″–6″) | 25 / 50 | 24 | MSCB-168E | MSCB-168A | MSCB-168N | MSCB-168H |

| MSCB-219 | Ø50–219 mm (2″–8″) | 25 / 50 | 23 | MSCB-219E | MSCB-219A | MSCB-219N | MSCB-219H |

| MSCB-273 | Ø114–273 mm (4″–10″) | 25 / 75 | 23 | MSCB-273E | MSCB-273A | MSCB-273N | MSCB-273H |

| MSCB-323 | Ø168–323 mm (6″–12″) | 25 / 75 | 23 | MSCB-323E | MSCB-323A | MSCB-323N | MSCB-323H |

| MSCB-355 | Ø177–355 mm (7″–14″) | 25 / 75 | 23 | MSCB-355E | MSCB-355A | MSCB-355N | MSCB-355H |

| MSCB-406 | Ø254–406 mm (10″–16″) | 25 / 75 | 19 | MSCB-406E | MSCB-406A | MSCB-406N | MSCB-406H |

| MSCB-457 | Ø323–457 mm (12″–18″) | 25 / 75 | 19 | MSCB-457E | MSCB-457A | MSCB-457N | MSCB-457H |

| MSCB-508 | Ø323–508 mm (14″–20″) | 25 / 110 | 14 | MSCB-508E | MSCB-508A | MSCB-508N | MSCB-508H |

| MSCB-559 | Ø355–559 mm (16″–22″) | 25 / 110 | 14 | MSCB-559E | MSCB-559A | MSCB-559N | MSCB-559H |

| MSCB-610 | Ø457–610 mm (18″–24″) | 25 / 110 | 14 | MSCB-610E | MSCB-610A | MSCB-610N | MSCB-610H |

| MSCB-762 | Ø610–762 mm (24″–30″) | 25 / 110 | 9 | MSCB-762E | MSCB-762A | MSCB-762N | MSCB-762H |

| MSCB-914 | Ø762–914 mm (30″–36″) | 25 / 110 | 9 | MSCB-914E | MSCB-914A | MSCB-914N | MSCB-914H |

| MSCB-1066 | Ø914–1066 mm (36″–42″) | 25 / 110 | 9 | MSCB-1066E | MSCB-1066A | MSCB-1066N | MSCB-1066H |

| MSCB-1240 | Ø1040–1240 mm (40″–48″) | 25 / 110 | 9 | MSCB-1240E | MSCB-1240A | MSCB-1240N | MSCB-1240H |