Description

| CAPACITY | Pipe: 1/4″ -4″(6MM-100MM} Bolt: 12MM-45MM |

| MOTOR | 1500W induction, 50 OR 60Hz SINGLE PHASE |

| SWITCH | Heavy-duty rotary Forward/off/reverse and integral foot switch |

| SPINDLE SPEED | 36/20/11RPM. |

| FRONT CHUCK | Hammer type with replaceable rocker action jaw inserts. |

| REMARKS | Rear Centering Device: Cam action. |

| Oiling System: Through the die head, with integral oil reservoir. | |

| STANDARD SUPPLY | Model FLARE.4C Threading Machine. (110 or 220V ) |

| Self-opening die head-SDHN71/SDHB91 { BSPT or NPT ) | |

| 1/4-2″ Self-opening Diehead-SDHN74/SDHB94 (BSPT or NPT) | |

| 2-1/2-4″ Yi”-%” universal HSS dies set. (BSPT or NPT) | |

| 1″-2″ universal HSS dies set. ( BSPT or NPT} | |

| 2-1/2″-4″ HS Die set. (BSPT or NPT) | |

| Cutter-MHC2032 : Capacity: 1/4″-4″(6mm-100mm) PIPE | |

| Reamer-MHR1010 : Positive-locking,5-flute cone, righthand 1/4″-4″(6mm-100mm). | |

| * 1Ga llon ‘Power Fluid PF-9835’ cutting oil. | |

| Supplied with MFS642 foot switch, MHlSOO wheel stand (Optional) |

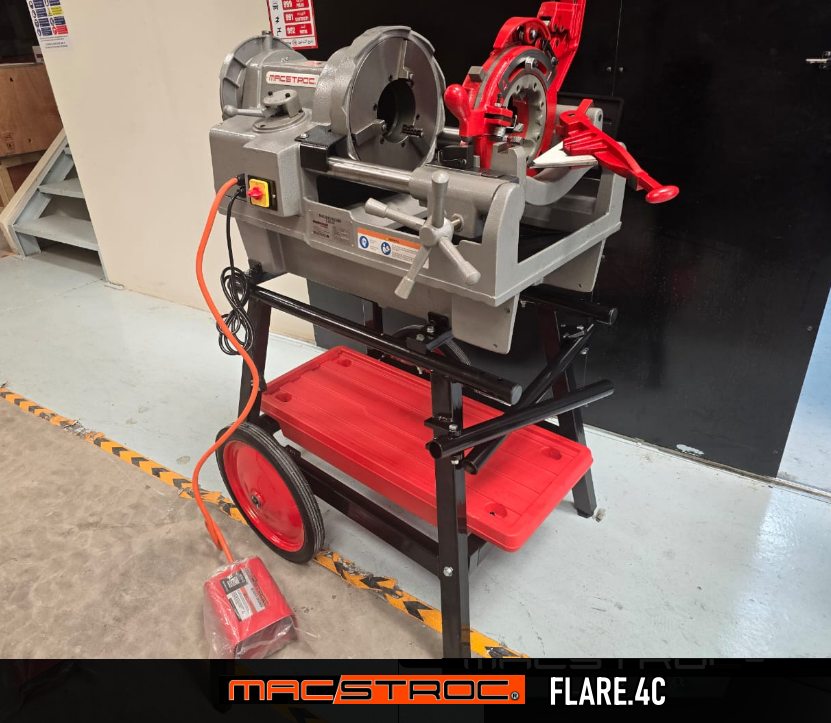

The pipe Threading Machine Flare 4C is a heavy‑duty yet portable power-threader, engineered for professional use in tight or remote job sites. Powered by a robust 1 500 W induction motor, it threads pipes from ¼″ to ¾″ at 36 RPM, 1″ to 2″ at 20 RPM, and up to 4″ with an optional geared attachment—all while maintaining consistent torque and precision.

Designed with mobility in mind, the Flare 4C is built on the MH1500 stand (CE-compliant), enabling easy setup and transport. Its forward/off/reverse rotary switch and integrated foot pedal allow seamless operation in either direction. Coupled with a hammer‑type front chuck and dependable threading performance, this machine is ideal for on-site plumbing, industrial, and maintenance teams in the UAE’s fast-paced environment