Description

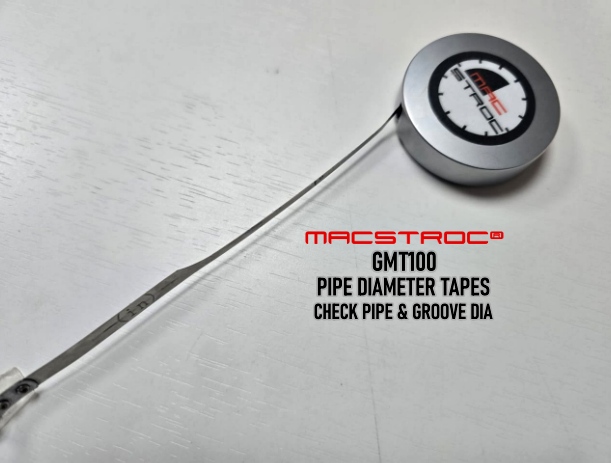

The Macstroc GMT-100 Pipe Diameter Tape Measure is a high-precision groove measuring tool engineered for professionals working with roll groovers and grooved pipe systems. Made from durable, flexible material, the GMT-100 allows quick and accurate measurement of pipe outer diameter (OD) and proper groove positioning from the pipe end. Essential for verifying groove placement according to industry standards, it helps ensure leak-proof, safe, and compliant installations with grooved couplings.

Whether you’re working in fire protection, HVAC, plumbing, or industrial piping, the Macstroc GMT-100 saves time, reduces errors, and boosts efficiency. Its compact design and easy-to-read markings make it an essential tool for every grooving technician and pipefitter.

How to Use a Groove Measuring Tape (Macstroc GMT-100)

For Roll Grooved Pipe Systems – Compatible with Victaulic®, Gruvlok®, and other Couplings

✅ Purpose:

The Macstroc GMT-100 Pipe Diameter Tape is designed to accurately measure pipe outer diameter (OD) and mark the precise groove location before grooving. This ensures perfect compatibility with mechanical grooved couplings such as Victaulic®, Gruvlok®, Anvil®, Shurjoint®, and others.

🔹 Step-by-Step Instructions:

1. Wrap the Tape Around the Pipe

-

Position the GMT-100 groove measuring tape around the pipe where you intend to groove.

-

Ensure it’s tight and level without twists.

2. Check the Pipe Outer Diameter (OD)

-

Read the OD from the tape where it overlaps itself.

-

Confirm that the pipe’s OD matches the required size for grooving.

-

This is critical to ensure proper engagement with grooved couplings like Victaulic or Gruvlok.

3. Mark the Groove Location

-

Use the printed reference on the tape to mark the correct groove distance from the pipe end (usually 2″–2.25″ depending on pipe size).

-

Groove location is based on industry specs (like AWWA C606) or coupling manufacturer’s standards.

🔧 For example: Victaulic couplings for 4″ schedule 40 pipe typically require the groove to be positioned exactly 2¼” from the pipe end.

4. Verify Straightness

-

Make sure the mark is perfectly perpendicular to the pipe axis.

-

For large pipes, rotate and recheck from other sides.

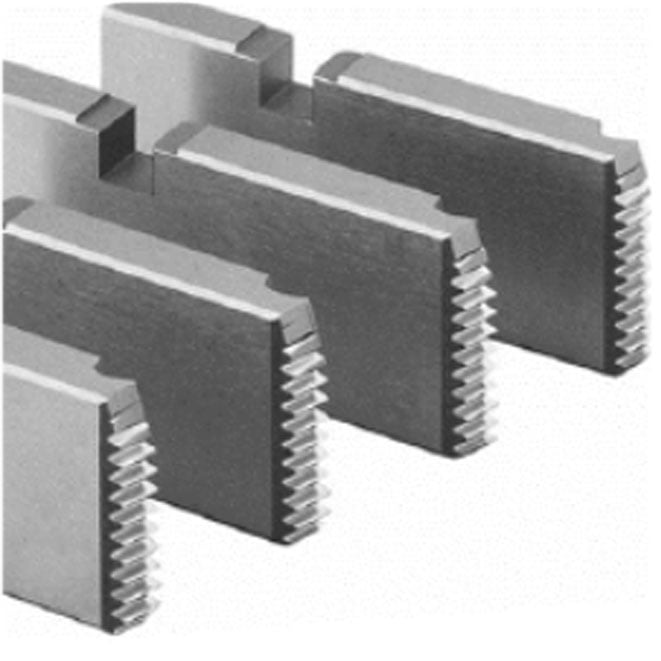

5. Roll Groove the Pipe

-

Place the pipe into the roll grooving machine (e.g., Macstroc MRG-12V2).

-

Align the grooving dies exactly at the marked line.

-

Groove the pipe to correct depth and width as per the coupling manufacturer’s specification.

🔍 Why This Matters with Victaulic®, Gruvlok®, and Others:

-

These mechanical couplings rely on exact groove dimensions for a secure, leak-proof connection.

-

An incorrect groove location or depth can result in:

-

Leaks or pressure failure

-

Coupling slippage

-

Void warranty or inspection rejection

-

⚠️ Best Practices:

-

Refer to the latest groove specs from the coupling manufacturer before marking.

-

Clean the tape and store it flat to avoid deformation.

-

Always re-check groove location for batch jobs or large installations.

✅ Conclusion:

The Macstroc GMT-100 groove measuring tape is essential for professionals installing grooved piping systems using Victaulic®, Gruvlok®, and other standard couplings. It ensures precise groove alignment, pipe OD accuracy, and compliance with mechanical joint standards, helping avoid costly rework or failure.